Kinetic Traction Systems

Company Name: Kinetic Traction Systems Inc.

Website: www.kinetictraction.com

Job Title: Consultant Design Engineer

Dates: September 2014 - August 2016

Location: Bristol, UK; Deeside, Flintshire, UK & Chatsworth, CA, USA

Key Skills Mix

"Founded in 2010, Kinetic Traction Systems, Inc. (KTSi) designs, develops and manufactures clean technology products for energy storage, power regeneration, waste heat recovery and turbo aeration applications. Product development is based on proprietary know-how and expertise in high-speed permanent magnet motors, magnetic bearings, power electronics and controls combined with advanced analytical capabilities. Kinetic Traction Systems’ products are designed to improve performance and efficiency, reduce energy consumption and lower carbon emissions, while providing innovative solutions to a variety of applications and industries in global markets. KTSi headquarters, research and development, and manufacturing are located in Chatsworth, California, USA with a design and application center in North Wales, UK."

Source: http://kinetictraction.com/

I first started working with KTSi after being approached for a position to work with a small project team of highly skilled external contractors from the likes of Williams F1 & Micheal Butler Creative.

Over the years I've worked on a number of projects and most recently on the design and development of a 4000 SCFM high speed centrifugal fan, with applications in the waste water and processing industries. For details of my involvement in each project please see below.

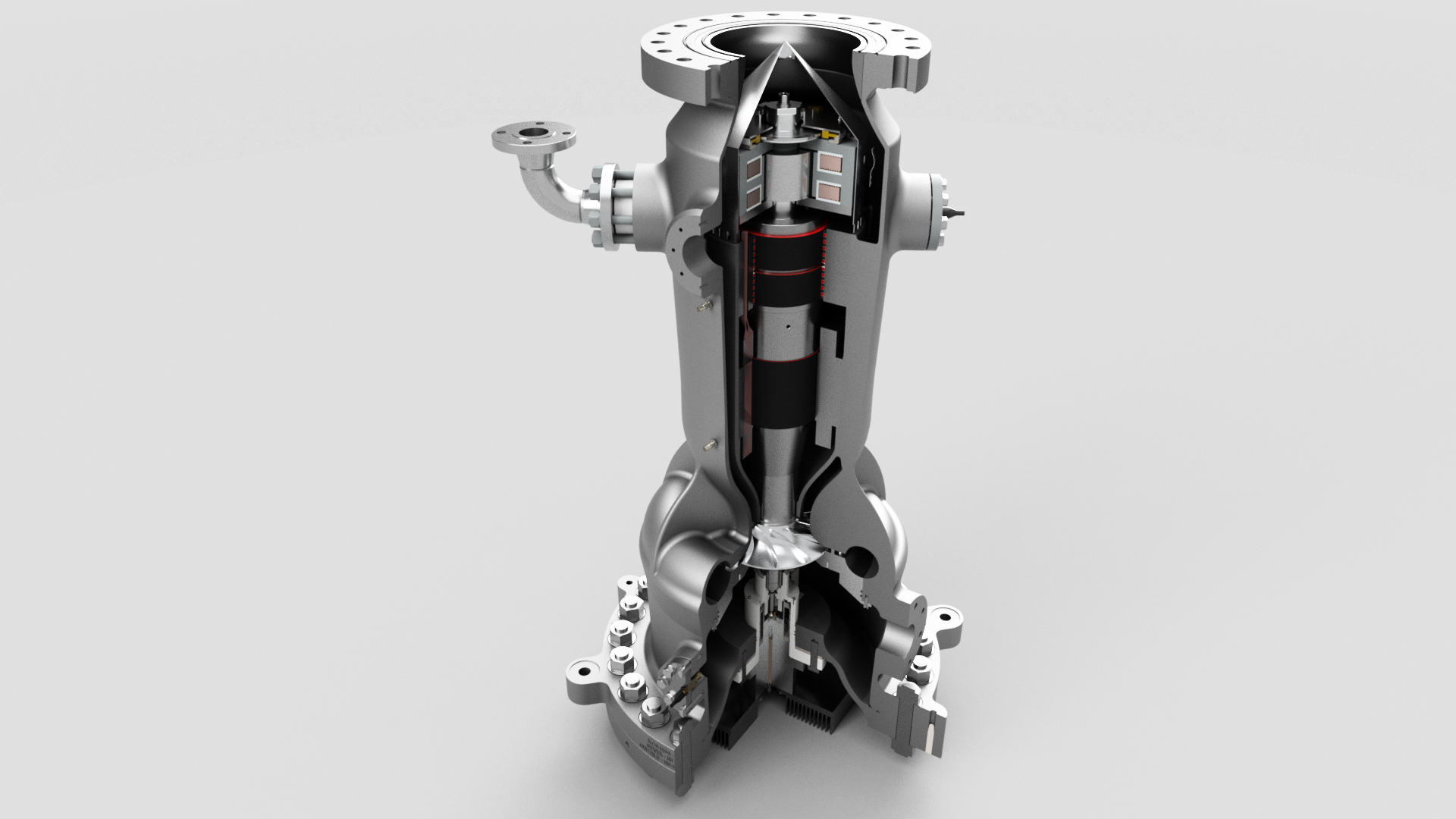

300 kW Waste Heat Recovery Generator (Organic Rankine Cycle)

I joined the WHRG project team in the later stages of the development process. Much of the design direction had already been defined and a manufacturing of the key components underway. My role was to assist the engineering team in the translation of the design and assembly intent into manufacturable components and subsequent technical documentation.

Due to the large forces involved and temperature differential between components - such as the generator stator and ductile cast iron housing - a number of critical limits and fits required defining. Using a combination of mathematical and computer aided numerical techniques I worked to define robust connections, taking into account machining capabilities for each of the critical interfaces. Examples of challenges I was responsible for solving include;

Detailed analysis of interference fits in a R-245fa pressurised environment using standard mathematical models and finite element analysis.

Assembly tooling design, development, testing & producing manufacturing packs.

GD&T utilising Solidworks DimXpert & TolStack for tolerance stack analysis.

Cost down activities such as replacing high cost per part metal components with polymer parts incorporating structural bonding.

Bolted joint analysis for key structural connections.

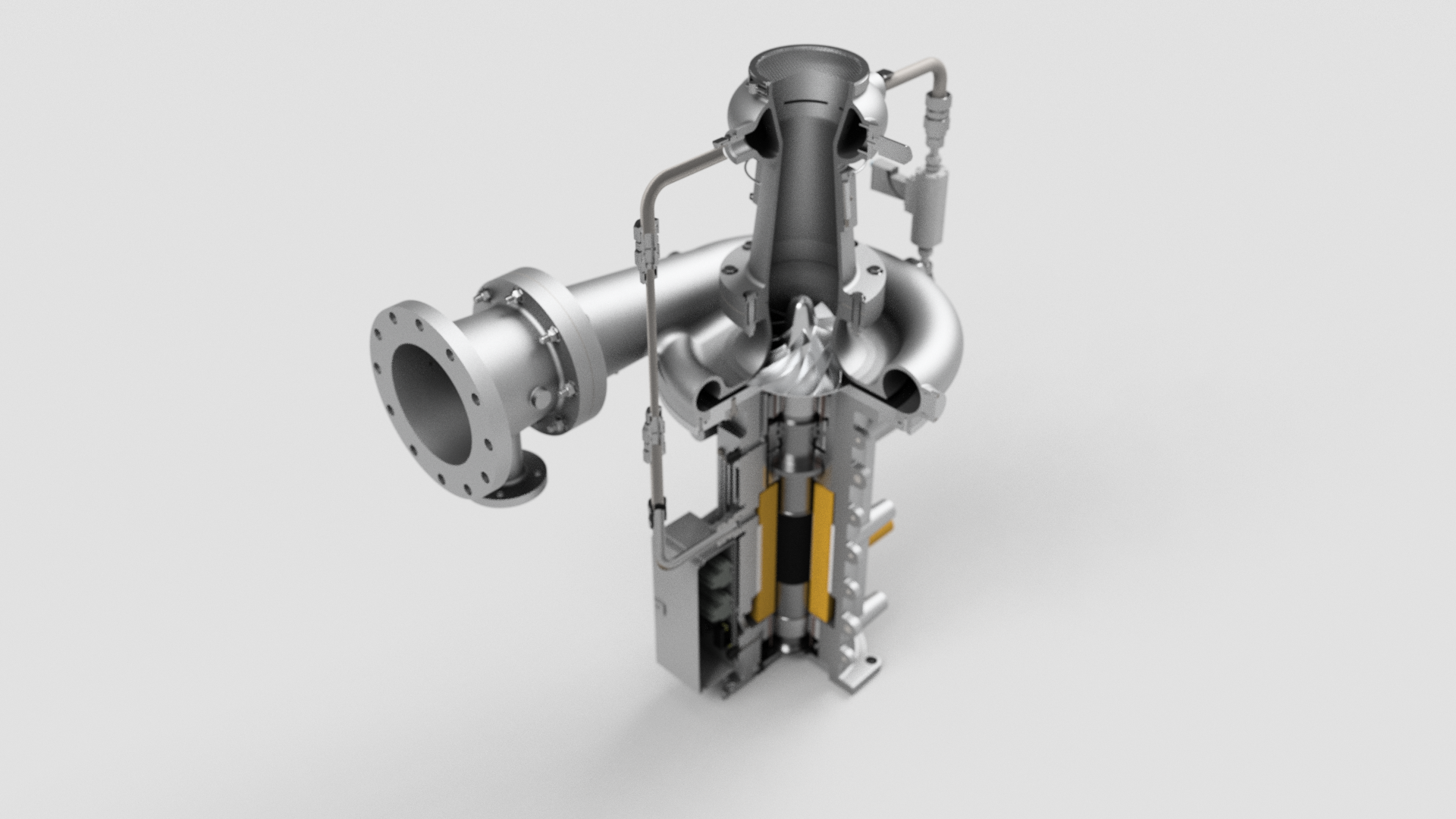

I began working on the development of the Turbo Aerator early in the product design cycle. Working with KTSi's engineering teams both in the USA & UK, as well as with specialist external suppliers we worked from first principles to design from the ground up a high speed centrifugal fan offering higher efficiency at increased turn-down ratios predominately for use in the waste water processing industry.

My focus were mainly on the mechanical, thermal and fluid flow aspects of the system's design but worked in conjunction with the external suppliers for key components such as the impeller and the 5 axis active magnetic bearing (AMB) system, both bespoke . Due to the high speed nature of the machine (27 krpm), structural dynamics played a key factor in the development of the rotating components as well as the bearing system, auxiliary bearing system and aluminium sand cast housing. Utilising computer aided engineering tools I ran multiple design schemes for shaft design and component configuration, minimising the effect of the overhung mass and ensuring shaft critical outside the operating range of the machine.

My involvement in the design and development of the machine incorporated all aspects from concept to assembly including;

Shaft design for structural integrity and dynamic performance.

Translating volute scroll geometry into sand casting minimising hydraulic losses.

Design of split housing sand casting incorporating conductive and convective thermal pathways for motor cooling.

Design for manufacturing - high speed rotating components, shrink & interference fits, castings, fabrications, pipework & electromechanical systems.

Design for assembly - non contact sensors, AMB system integration, cable routing, sealing, environmental packaging.

Magnomatics

Key Skills MIx

Company Name: Magnomatics Ltd.

Website: http://www.magnomatics.com/

Job Title: Mechanical Design Engineer (Contract)

Dates: April 2013 - October 2013

Location: Sheffield, South Yorkshire, UK.

Magnomatics is a high technology engineering company that is developing and manufacturing products for many global industries based on its proprietary ground breaking magnetic gear technology.

Magnomatics have developed two derivative products based on magnetic gears, the Pseudo Direct Drive PDD® and MAGSPLIT®. The PDD is a very efficienct high torque low speed motor/generator highly suited to rail traction, actuation, fan motors, marine propulsion and wind power. MAGSPLIT is a very efficient power-split hybrid transmission and is being evaluated by a number of vehicle manufacturers. MAGSPLIT is very simple having just two rotating elements and has the added benefit of filtering torsional vibrations.

The company is active in many market sectors, including hybrid vehicles, renewables, marine propulsion, aerospace, rail, and oil & gas.

- http://www.magnomatics.com/

I began contracting for Magnomatics shortly after leaving Slipstream Engineering Design. As my first contract position I couldn't have asked for a better client, giving me the opportunity to get involved in a number of key projects. As a high tech dynamic engineering company it was clear to see that right first time was key to the success of the business, coupled with a technical and management team with a clear vision for getting their novel technology into all industries that could benefit from efficient drive technology.

My role focused on realising the technical direction of the lead engineers into manufacturable products suitable for customer technology demonstration & test validation. I predominantly worked on products in their PDD product group which included;

Wing flap actuator for an Italian aerospace OEM.

Lightweight, modular multi megawatt drive for a global renewable energy consultancy.

High utilisation in wheel electric vehicle (EV) motor for commercial vehicles.

In addition to working on PDD products I was also tasked with root cause analysis of a high speed turbo shaft failure using numerical & analytical techniques for a tier 1 global automotive OEM and a multi axis test rig for the static & dynamic testing of electrical machines suitable for torsional loads up to 6kNm & equivalent magnetic loads of up to 3kN.